PTP Manufacturing has the skills and capability to produce tooling and fixtures in-house. Why is this important to you? From the time we first see your request for a quote and specifications, we are looking for ways to produce your part accurately and economically. PTP Manufacturing does not look to fit your project in our “box”, but rather we strive to tune our CNC plastics machining and turning centers to your needs.

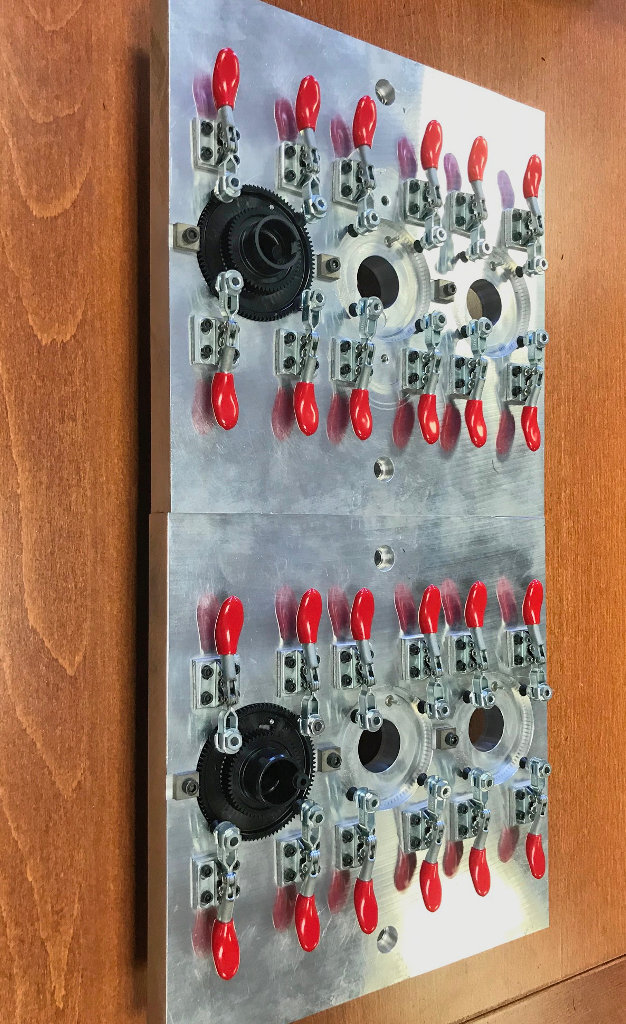

We create custom tooling and fixtures that may be necessary to machine a specific part. We utilize custom fixtures to accurately and efficiently position raw materials, molded plastic parts, or process materials in our machining and turning centers.

Since each customer’s project is unique, we often make custom tooling and fixture to get the job done. Much like a cookie cutter is used to turn a lump of dough into a desired shape, efficient tooling is used to turn raw materials into the parts you need. Think of this analogy: you could make gingerbread cookies with dough, a rolling pin, and a knife, but how efficient would that be? In many cases the custom tooling we create can have the productivity impact of changing from the aforementioned knife to a cookie cutter. PTP’s efficient use of labor and machining and turning centers makes producing your plastic machined products more efficient and cost-effective.

Why should you care that tooling and fixtures are done in-house? First, it allows us to quote you at a lower rate, saving you money and improving your bottom line. Because we can make custom tooling and fixtures right at our location, we save the time and money of outsourcing. These savings are passed on to you, the customer. For an order of large volume, you will never see the cost of producing custom tooling and fixtures.