Are you facing challenges maintaining precision in plastic molded parts? Plastic machining may be the answer for plastic parts that cannot be molded with the precision you or your customer require. For plastic molding companies or their customers, it can be a struggle to find strategies that enable the proper production of intricate components. Outsourcing your plastic machining services is often more economical if you are doing in-house plastic molding for your own use.

Whether you are looking to machine bigger or smaller parts and plastic pieces, advanced precision machining processes offer valuable opportunities for superior-quality parts. This blog post will discuss the fundamentals of precision machinery and how it applies to molding projects. Precision plastic machining can:

- Improve part accuracy

- Bring higher levels of structural integrity

- Allow faster turnaround times

- Lower the risk of product defects

Struggling to perfect a complex injection molded part? Let the experts at PTP Manufacturing take over. With years of experience in precision plastic machining, we’ll develop an efficient process that will bring your part to completion with accuracy and reliability – giving you more time to focus on what matters most. In addition, our plastic machining solutions allow you to simplify your plastic molding process. This will enable both less expensive molds but quick production and end with the precision you need at an economical price. Whether you need batches of 10 parts, or 2000, we have the tooling and expertise to meet your needs.

Project Case Study: Pharmaceutical Industry High-density Polyethylene Molded Part

Our customer crafted a precisely contoured glove port from high-density polyethylene material. With two different blue plastic ovals, one on the exterior and another on its interior side, this part is essential in providing secure access to machines used within pharmaceutical production lines. As you can guess, any defects in the molded plastic materials or the final dimensions of the part cannot be tolerated.

PTP Manufacturing was presented with unique challenges – the customer provided two sample parts. While they were a set, each had its own machining requirements. While both were similar, each had differences regarding required secondary operations. The first featured the need for high-precision double O ring grooves on its exterior along with removing and mold gating material from the interior. In contrast, the second part necessitated a single groove and also needed mold gating material removed from the interior. Both needed to be machined correctly so that their glove ports could create seals when joined together around rubber sleeves and finish without any sharp edges or voids present. Any defect in the final plastic parts that would cause a leak or tear of the sleeve was not acceptable.

Project Challenges

PTP Manufacturing’s innovative engineers faced a challenge: to create two custom fixtures that would streamline the machining process and save on costs. While inventing this repeatable process, our main challenges were inconsistent part placement due to raw molding variations and vibration-induced chatter. Undaunted, they tackled these typical problems head-on for an efficient resolution!

What is Chatter?

Chatter is an undesired phenomenon in parts machining, particularly in cutting and milling. It produces undesirable effects during the machining process, such as vibrations at the cutting point, making it more difficult to achieve precise results due to chatter marks. Additionally, chatter increases cycle times and tool wear due to the parts vibrating against one another. This can lead to production delays and increased costs due to pricey repairs or parts replacement. Thus, controlling chatter is an important consideration when parts machining is needed.

The problem of inconsistently molded parts

In plastic molding, inconsistently molded parts can create a number of problems. Without consistent and accurate plastic molding, plastic parts may not fit together or may break quickly due to structural weakness. On the assembly line, time and money are wasted if plastic parts must be discarded for inconsistency or not meeting specifications. Quality control measures are necessary to ensure that plastic molding achieves uniform consistency and density to maximize cost savings and longevity of plastic products.

However, in many cases, the solution is to mold a simpler part or mold it with increased tolerance and rely on plastic machining to bring the part to the needed precision. This often increases your production rate, lowers costs, and increases reliability. Modern CNC machined plastic parts may be necessary in delivering the precision plastic components you need.

Solving the problems

We designed two steel fixture plates with clamps surrounding the flange to guarantee accuracy and rigidity during the plastic machining processes. This allowed us to hold each part secure within these fixtures during machining. Pinpoint contact points along the inside diameter provide the precise part location, ensuring optimal machining results. In addition, cycle time was reduced as placing the part for the machining process is now easy. Even the best CNC machining processes will not produce accurately machined parts if it does not know the precise location of the raw part!

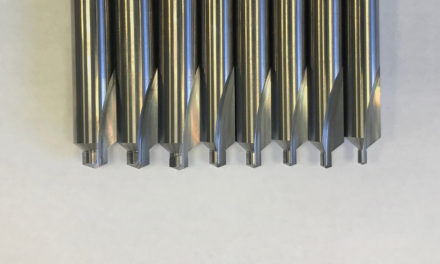

The next “tool” in our arsenal was, you guessed it, the tooling. For complete accuracy crafting a tailor-made tool was the best next step. Therefore we designed a custom tapered end mill to machine the inside diameter. In addition, we then found a two-flute radius router bit that would be effective at machining the double O ring groove. These creative tooling solutions successfully eliminated all chatter while machining the parts

In the case of this project, our ability to consider the mechanical properties of the raw plastic workpiece and carefully evaluate the best fixtures and carbide tooling we needed to use. Using a custom tapered end mill, the cnc milling done for our customer removed material related to gating that could have caused their customer problems later. In addition, the accurate milling of the O ring grooves lets them continue using their material selection and maintain the air-tight seal their customer requires.

Why use a plastic part?

Are you considering replacing a stamped or cast metal part with a molded thermoplastic part? Today’s plastic materials are more flexible than ever. Here are some important advantages of molded and machined plastic parts.

Reduced Cost

Molded and machined plastic parts are typically less expensive to produce than those made from other materials, such as metals or glass. This is due to the fact that plastic is a less expensive material overall. Additionally, molded and machined plastic parts can be produced with fewer steps than those made from other materials, which further reduces their cost.

Increased Design Flexibility

Molded and machined plastic parts offer increased design flexibility when compared to those made from other materials. This is due to the fact that plastic is a more flexible material overall. Additionally, molded and machined plastic parts can be designed with specific reinforcement features, such as ribs or gussets, that further increase their design flexibility.

Increased Chemical Resistance

Molded and machined plastic parts offer increased chemical resistance when compared to those made from other materials. This is due to the fact that plastic is a more resistant material overall. Additionally, molded and machined plastic parts can be designed with specific reinforcement features, such as ribs or gussets, that further increase their chemical resistance.

Corrosion-Resistant

Molded and machined plastic parts are also resistant to corrosion. This is due to the fact that plastic is a non-reactive material that does not rust or corrode when exposed to moisture or other elements. This makes molded and machined plastic parts ideal for applications requiring corrosion resistance, such as in the food and beverage industry.

Lightweight

Molded and machined plastic parts are typically lighter in weight than their metal counterparts. This makes them easier to transport and handle, which can be beneficial in a variety of applications.

Versatile

Molded and machined plastic parts are also very versatile. They can be produced in a wide range of shapes, sizes, and colors, making them suitable for use in a wide variety of applications.

Economical To Machine

Machining plastic is done with the same computerized numerical control (CNC) machines that are used for metal machining. However, there is less tool wear, enabling low-cost machining of most plastics. The combination of molding and machining is well suited in delivering high-precision parts when paired with the right material.

PTP Manufacturing, your key to creative plastic CNC machining

At PTP Manufacturing, our innovative approach to secondary machining operations allowed us to provide a unique solution for one of our customers’ injection molded parts needs. With an experienced team on board and cutting-edge technology at their disposal, we’re ready and willing to assist with your own special project.