Production CNC Machining

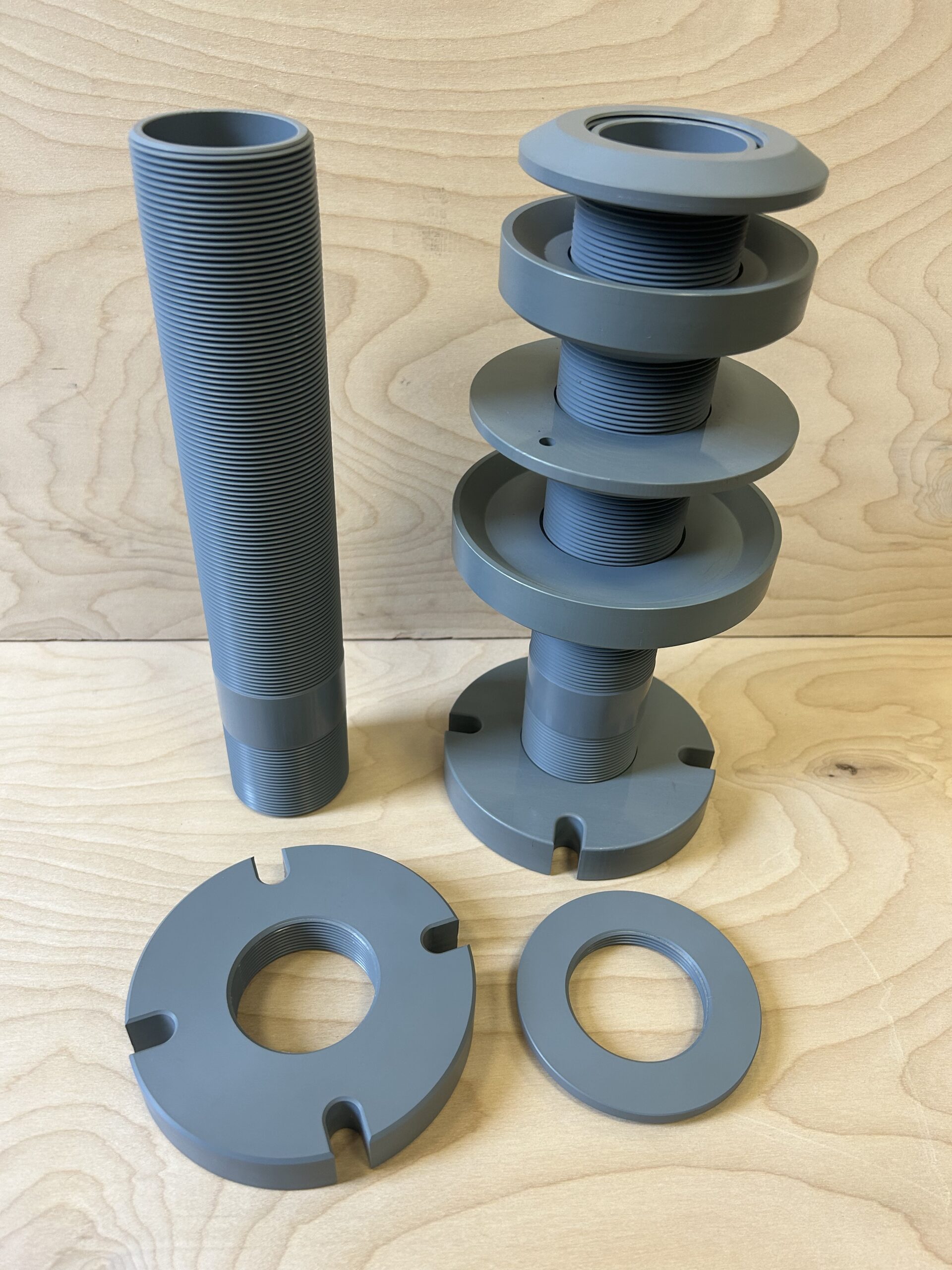

One of PTP Manufacturing’s specialties is providing CNC (Computer Numerical Control) machining services, particularly specializing in plastics. We use CNC machining to add value to both molded parts and raw plastic stock. These advanced processes have come a long way from the conventional manual manufacturing process of years past.

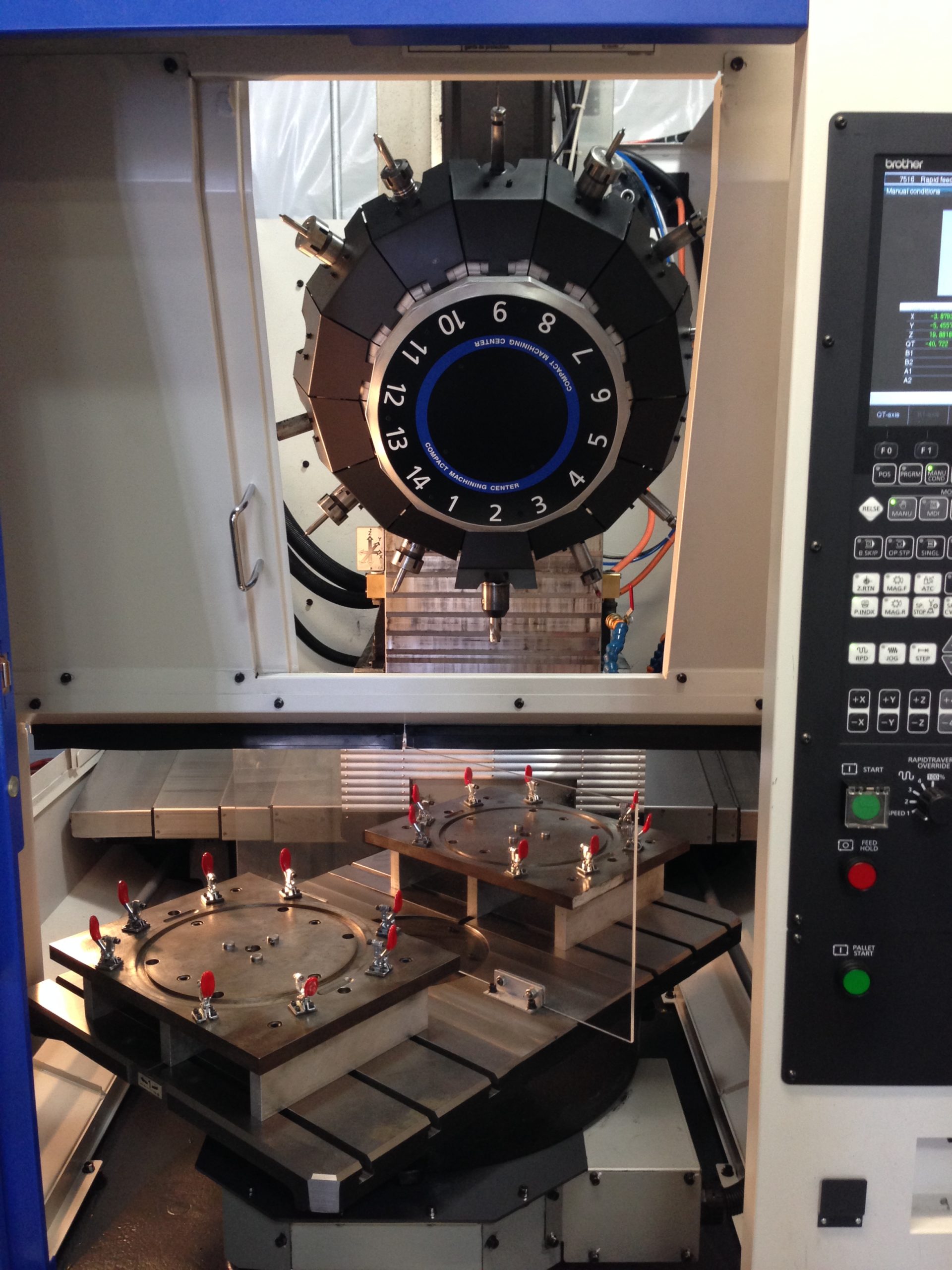

What does this mean to you as a customer? Our palletized CNC machines use automation to cut out the potential of human error and produce your order with speed and accuracy. You receive the benefits of economical plastic part machining without compromising on quality. The machines at our facility are highly versatile and able to work with a number of different materials. We specialize in plastics, including PVC, glass-filled and nylon, but can work with almost any plastic material that you require.

MATERIALS LIST (Your material not on the list? Just ask!)

• ABS

• ABS (MOLDED)

• ACETAL

• ACRYLIC

• DELRIN

• GF (Glass Filled) DELRIN (MOLDED)

• PVC

• CPVC

• NYLON

• GF (Glass Filled) NYLON (MOLDED)

• NORYL

• GF (Glass Filled) NORYL (MOLDED)

• PHENOLIC (MOLDED)

• POLYCARBONATE

• POLYURATHANE

• PTFE (TEFLON)

• GF (Glass Filled) PTFE

• PEEK

• TPUR (MOLDED)

• PA66 (MOLDED)

• UHMW

• URETHANE

• ULTEM 1000

• ULTEM 1000 (MOLDED)

Our Brother machining centers have the following size capacity.

X axis = 450 MM

Y axis = 320 MM

Z axis = 505 MM

From the time we first see your plans, we are looking for opportunities to save you money with efficiency. We often produce tooling and fixtures to reduce the cycle time.

Many of the plastic machining projects we perform are used in water treatment and control. We offer NSF traceability through the sourcing and manufacturing process, so you have the documentation you require for your products.

We do not use cutting lubricants, so your parts arrive clean and free of chips or other contamination. This will help you during assembly and any marking or printing processes you will use during production.

We can also work with certain metals, such as some steels and brass. While we specialize in plastics machining and turning, if you need metal parts independently, or as inserts to your plastic parts, we can be your one-stop-shop for both.

PTP Manufacturing has worked with clients in many industries such as agriculture and water treatment and control, hand and pneumatic tools, and many more.

When it is time for you to request a quote, please use our “Request a Quote” form. You may provide your part specification as a PDF drawing or Solidworks auto CAD (Computer-Aided Design). You can provide us with your drawings either physically or electronically, whichever is most convenient for you. We have the flexibility of working with both metric and imperial measurements depending on your preferences.

At PTP Manufacturing we know you have high standards for your parts. That is why we focus on using the most efficient and reliable processes and tools in the industry. We want to save you time, energy, and cost. Using CNC machining means that we have flexibility in the materials we use and the capability to do complex machining to suit your needs. Whatever the size of your order, we will get the job done quickly without sacrificing accuracy or quality. You can depend on us to deliver quality and economical components for your products.