If you require precise plastic parts, you may think that attempting to produce the parts in-house is your best option. This is a common misconception. Increasingly, businesses are discovering clear advantages to outsourcing the production of precision plastic parts to specialized machining facilities. Outsourcing often lowers costs and increases precision. Whether you are an OEM or a secondary supplier, there are many benefits to letting our PTP Manufacturing team expertly handle all your plastic machining needs.

There is a reason that we have a reputation as being one of the best in the plastics machining industry. At PTP Manufacturing, we excel in (computer numeric control) CNC machining services, specializing in plastics. Our high-tech CNC machines use automation to eliminate human error and provide fast, accurate results that meet the highest standards for precision. Thanks to our versatile machining capabilities and expertise, we can work with almost any plastic material, including PVC, nylon, and glass-filled options. Here are 6 significant reasons to outsource our plastic CNC machining to the professionals at PTP.

#1 – cut production costs

Outsourcing to a specialized plastic production machining company can often be more cost-effective than setting up an in-house machining facility. Purchasing precision milling and drilling machines and training your staff to use them is extremely costly.

At PTP, we have already invested in top-of-the-line equipment and skilled machinists, which means we can often provide services at a lower cost than an in-house operation. Especially with lower target volumes, investing in your own equipment will ultimately leave you in the red.

There are specific ways that outsourcing your plastics machining will save you money:

Labor Costs:

Having trained and knowledgeable operators is essential to maximize your machinery investment. However, maintaining a dedicated staff to operate those CNC machines may not be feasible. By outsourcing this function, you can focus your time and team on other critical areas such as design, engineering, and molding. Even if you outsource your injection molding, you will still save indirect labor costs by having the right provider focus on what they do best. Let our professionals at PTP handle machining proficiency so you can stretch your budget and enhance your return on investment.

Equipment costs:

In order to conduct in-house plastic machining, you must have the appropriate equipment, which is a considerable investment. Besides the cost of cutting-edge CNC machines capable of producing your products, you will require additional fixtures and quality assurance. Unless you undergo large runs for a long period of time, there is little potential for your equipment investment to yield a return on investment. Keep in mind that there are other expenses related to the ownership and operation of machinery, like maintenance and repair, that must also be considered.

Maintenance Costs:

Specialized precision machines are made of many complex parts, which means that proper maintenance is also highly complex and requires in-depth knowledge of the equipment. Maintenance of these machines not only depends on properly trained personnel but also requires an investment of time. Machining operations come to a halt while they undergo maintenance, which costs you money in the form of time. At PTP, our facility is fully equipped to continue running efficiently even if one of our precision CNC centers is being maintained.

Scale Costs:

By partnering with PTP Manufacturing, you can benefit from our plastic machining experience for your lower-scale projects. We have the advantage of having the volume that supports the specialized equipment needed to perform your precision plastic machining efficiently. The advantages of economies of scale extend beyond these benefits to encompass equipment and maintenance expenses. If you managed your plastics machining process in-house, you would need to produce extremely large volumes of product in order to break even on production costs.

#2 – Quality Control

PTP Manufacturing has strict quality control measures to ensure our products meet the highest industry standards. Our CNC machines are palletized and operate using automation, ensuring precise and speedy production of your orders.

Not only do you enjoy the benefits of economical plastic part machining, but we also guarantee that the quality of your parts is never compromised. Through continuous monitoring of the production run and sampling of your parts, we remove the potential for tool wear and other factors that may affect the quality of the output. You can rest assured that with our cutting-edge technology and vigilant quality control, you’ll receive premium plastic parts without sacrificing cost-effectiveness.

#3 – Faster Time to Market

Partnering with PTP Manufacturing means you will also cut down your production time. Outsourcing can help companies bring their products to market faster by providing faster turnaround times on machining orders. This is especially beneficial in industries where time-to-market is critical.

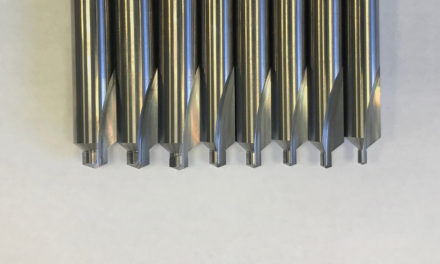

At PTP Manufacturing, our machine shop is set up to streamline your plastic machining needs. Our state-of-the-art facility contains top-notch lathes and milling machines that get the job done right the first time. If you need custom tooling and fixturing, we design custom tools and fixtures in-house, which saves you both time and money. Shorter lead times make happier clients for us and your customers. Send us your CAD file, and you can expect finished parts quickly without the risks of long supply chains and shipping delays. In fact, we have our own trucks to deliver directly to our customers, at no cost to you.

#4 – Access to Expertise

Our team at PTP has highly skilled and experienced machinists who are leaders in the field. Each type of plastic requires different machining techniques, depending on the composition of the plastic. The precision machining process is not universal for every project and differs from most other machining processes.. Some of our customers rely on us to create a part from raw material, while others only need specific machining of aspects that cannot be reliably injection molded. No matter the parts state, we can perform the operations you need to have a product-ready part. Outsourcing to our company can provide access to the expertise you need for proper plastic fabrication, which can be difficult to replicate in an in-house operation.

The complex and nuanced process of plastic machining requires a combination of artistry and scientific know-how. Despite the wealth of information available on best practices, nothing can compare to the expertise gained from our years in the field. Our experienced engineers can fine-tune the process with a level of precision that assures quality products, troubleshooting, short turnaround time, and more. This is critical to keep prices and lead times competitive for all of our customers.

Our expertise at PTP also means we can deliver your parts, support, and customer service that wouldn’t be available if you attempted machining in-house. Our production support can assist with every aspect during the entire process, from conception to fulfillment. We can step in or out at any time to meet your specific needs and ensure your project is completed on time and on budget. Outsourcing your precision machining needs provides you with the peace of mind that you will get the best service at every step, should any changes or problems arise.

#5 – Scalability

Specialized manufacturers like PTP benefit from economies of scale, allowing for larger production runs and cheaper costs. This allows us to produce parts at a larger scale, lowering the per-unit cost.

Outsourcing plastic production machining allows companies to easily scale production up or down as needed without having to invest in additional equipment or staff. This can be particularly useful for companies with fluctuating production demands. If your production demands are inconsistent, retaining the staffing needed for both low and high-demand times will be hard. PTP Manufacturing consistently has the equipment and staffing needed for your plastic machining needs.

#6 – Varied capabilities

At PTP Manufacturing, we don’t limit ourselves to a one-size-fits-all approach. Instead, we adapt our CNC plastics machining and turning centers to meet your requirements.

We create custom tooling and fixtures to machine your unique parts precisely. Our machines use these specialized fixtures to position raw materials or your raw parts accurately. Custom fixtures, tooling, and programming let us work with whatever materials are best for you, whether injection molded plastic components or raw stock.

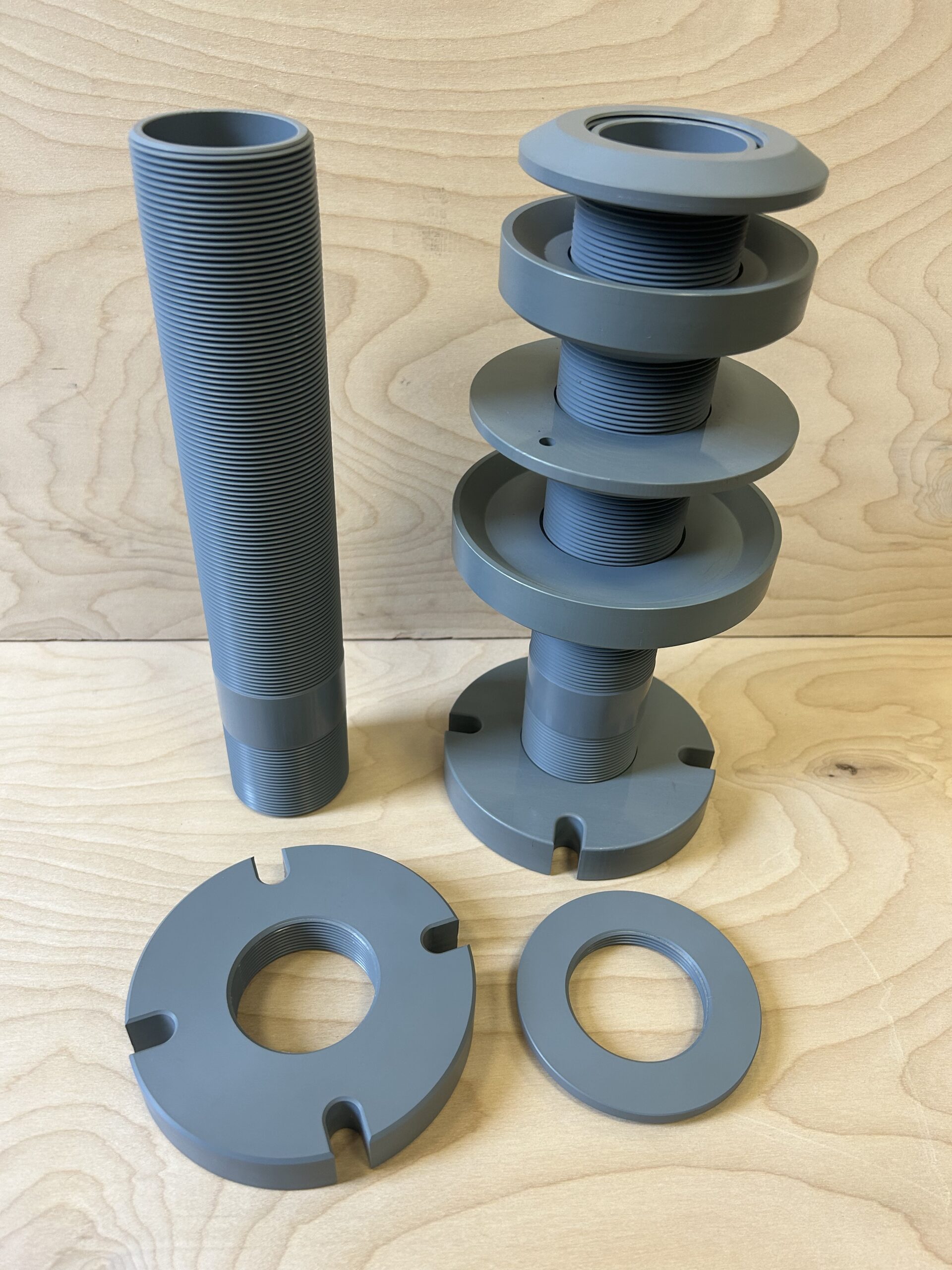

Since each project is distinct, we often design custom tooling and fixtures to achieve our goals. Our machines work with a wide range of materials, including PVC, glass-filled, and nylon, and we can process almost any plastic material you need.

Our Mazak turning lathes are state-of-the-art. We can produce a variety of threaded, tapered, bored, or other shapes, as needed, pre- or post-process machined or molded plastic parts. Our machines can handle all sizes of parts with ease.

Why outsource plastics machining in the United States?

You may be tempted to cut costs by outsourcing your machined plastic overseas to Chinese or other off shore manufacturers. Here are some significant reasons to consider choosing a US-based company like PTP instead:

1. A Higher Standard of Safety and Quality Control

Close proximity to your production facility ensures tighter control over the manufacturing process and materials that conform to safety and quality standards, guaranteeing that all products meet set regulations and specifications. In case of any problems, you can quickly identify and rectify them, saving valuable time and resources. U.S. manufacturing guarantees greater safety practices in vendor facilities, safeguarding your reputation with your customers. Outsourced manufacturing in countries with lax regulations puts your company at a higher risk of receiving lower quality, or even bad parts.

2. Shorter Lead Times

Manufacturing in the United States saves you money on logistics costs and speeds up the production process. With shorter distances to your facility, products are delivered faster, boosting sales, enabling agile forecasts, and increasing revenue. By meeting expectations for timely deliveries, you’ll keep shipping costs low for yourself and your consumers. Short lead times are also key to customer satisfaction.

3. Better Customer Service

Keeping your production on American soil provides more benefits than just high-quality parts. It also ensures top-notch customer service for your business. The geographic location of your service representatives has a significant impact on the quality of your business relationship. Relying on offshore customer service centers can create communication barriers, language differences, and time zone issues, resulting in increased problems and frustrations for both parties. Avoid these challenges by keeping your customer service onshore with qualified American professionals.

4. Reduced Delivery Cost

Manufacturing facilities abroad have commonly been used to save on labor and production costs, but shipping costs have increased exponentially. You can save significantly on inbound and outbound delivery costs by choosing to manufacture in the United States. Domestic shipping also provides a wider range of transportation options and broader shipping windows to offer even greater savings. You’ll also eliminate the risks of language and currency barriers when working with American delivery companies, resulting in a smaller margin for human error. Invest in keeping your production in the USA and save big on shipping costs. PTP Manufacturing can also offer pickup and delivery, using our trucks, at no cost to you.

Why choose PTP for plastics machining?

At PTP, excellence is not just a goal; it’s a standard. Our unwavering commitment to delivering top-notch products has been the cornerstone of our success. We have a proven track record of providing quality and precision machining services to diverse customers. We use only the finest equipment and employ the best procedures to ensure your complete satisfaction. From the moment we receive your drawings and specifications to the moment you receive the finished product, your contentment is our top priority. We take pride in being your provider of choice for plastic machining services, and we offer affordable pricing to ensure you get the best value.

As you can see, outsourcing plastic production machining can provide a cost-effective, quality-controlled, and flexible solution for companies looking to produce high-quality plastic parts. Contact our team at PTP Manufacturing and let us show you how we can deliver you a product that meets your needs and exceeds your expectations.